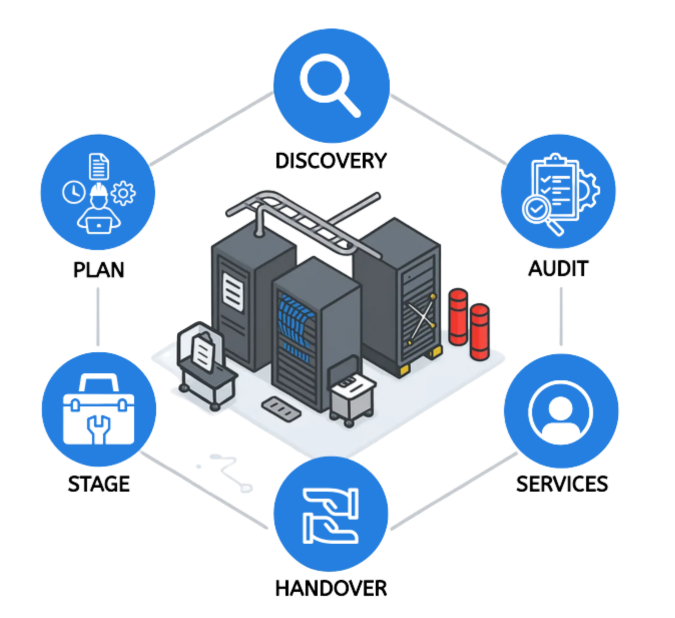

We coordinate end-to-end: audits, ID schemes, pre-cable/pre-label staging, populated rack logistics, chain-of-custody, re-site validation, and documentation. Your PM owns the plan, scope, risk, resources, comms, approvals, and evidence—from the first discovery call to the signed handover.

We wrap every migration in a TIA-606 governance layer owned by one PM, then plan not just the move but the change: rack consolidation/rightsizing, platform swaps, and tech refresh. The team locks the ID scheme, label matrix, port maps and a design freeze, raises procurement for new kit (racks, PDUs, optics, transceivers) and cable procurement (Cat6/6A & OM4/OS2—bulk reels vs exact lengths, spares policy, lead-time tracking).

We lock the runbook, route/lift plan, RAMS/permits and escalation lanes before the window, then drive a steady rhythm—weeklies in staging, dailies pre-cutover, hour-by-hour during change. CAB gates and a live RAID keep decisions fast, traceable and aligned across facilities, security, carriers and smart-hands.

Readiness gates confirm kit, pre-cabling, route protection and rollback; we timestamp each step and deliver tests, photos and brief hyper care.

Confirm sites, windows, business constraints, security, and success criteria; gather inventories and live-risk context.

Publish gantt, RACI, RAID, and communication plan; lock ID scheme, port maps, label matrix, and acceptance tests.

Track procurement and pre-cabling (bulk vs exact lengths), QA photos, bag-by-RU kitting, and rollback materials; readiness checklist to “go".

Runbook-driven tasks with timeboxed steps; populated racks braced, covered, dollied/skated, shock/tilt logged; GPS-tracked custody.

Position and level; reconnect A/B power; dress & segregate; Fluke DSX (copper), LSPM/OTDR (fibre), airflow checks, screenshots/photos.

Issue as-built, test packs (PDF), photo record, exceptions list, and actions; final sign-off and lessons learned. Handover of Infrastructure Planner.

A live RAID and CAB-ready change packs (runbook, rollback, go/no-go) sit beside route & lift plans, permits, security/insurance, and dedicated vehicles, so decisions are evidence-based, not improvised.

Staging covers pre-cabling and kitting by RU, but also decommission/commission flows: serial capture, asset tags, BIOS/firmware baselines, and ITAD for retired gear (certified data wipe/shred, WEEE-compliant recycling, resale where viable). Populated racks are braced, covered, dollied/skated, with shock/tilt logging and GPS custody; new hardware lands from procurement with DOA checks.

On arrival we re-site, level and validate: Fluke DSX (copper), LSPM/OTDR (fibre/MPO), A/B power load/continuity, airflow photos and connectivity tests. Handover includes as-builts, test packs, photo record, exceptions list, and updated inventories—so operations inherit a footprint that’s consolidated, refreshed, and provably ready.

Want to find out more?